Super-Fast 3D Printing Technique: Resin Objects Created in a Few Seconds

In its early days, 3D printing was principally used for creating prototypes rapidly. But the technology has evolved through the years. The printing technique’s material range, repeatability, and precision make it a viable tool for industrial production. One of its primary advantages is producing complex shapes that are almost impossible to create by hand, such as creating parts with internal truss structures or hollow parts to help reduce the product’s weight.

New light-based process

The research about various applications of 3D printing continues. The researchers at the Swiss Federal Institute of Technology Lausanne or the École Polytechnique Fédérale de Lausanne (EPFL) recently demonstrated a new 3D printing method. Using a light-based method, which is 30 times faster than mainstream additive manufacturing, they created objects in 20 seconds. Using the conventional way, it would take ten minutes to develop. By using photocurable resins, the scientists achieved a shorter or faster production time.

According to Prof. Christophe Moser of the Laboratory of Applied Photonic Devices at EPFL, their light-based process, which they developed in 2017, approaches the process differently, resulting in a much faster production speed.

The professor said they poured the resin into a container, spun it, and shone a light on the container from different angles. The process solidifies the resin when the accumulated energy in the material exceeds the normal level. According to the research team, this method is precise, and it can produce items at the exact resolution as the existing techniques in 3D printing.

Using this technique, they can build many things quickly. Likewise, the process can print complex shapes without requiring the support structures usually needed when using a flatbed printer.

Resolving an existing issue

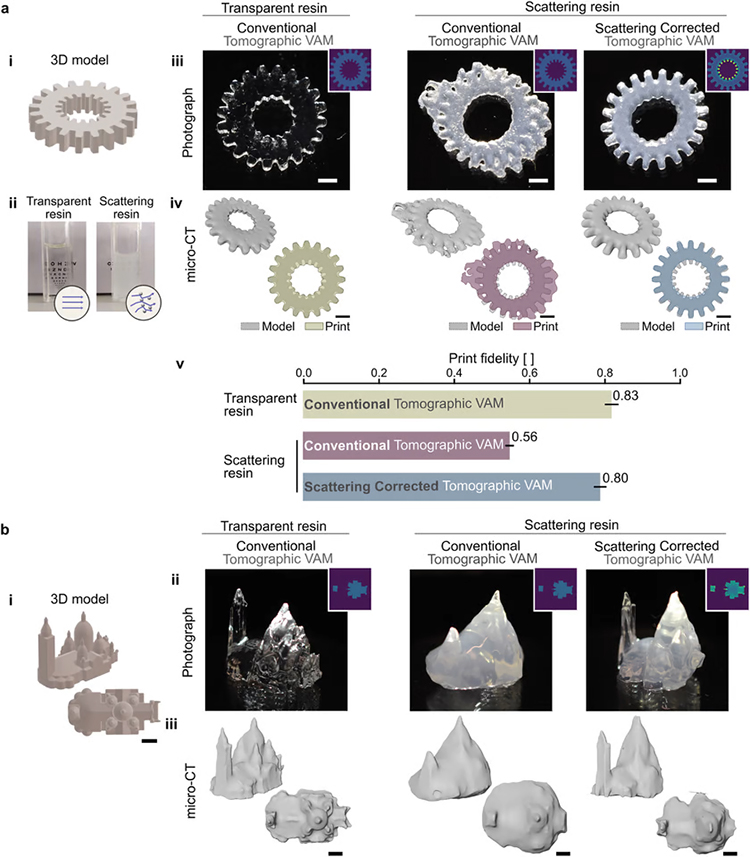

Up until now, the researchers said that the process requires typically using transparent resins. If they use resins with just a trace of color, such as the opaque resins used for printing artificial arteries for the biomedical sector, the light will bend and distort, making the printed objects lose resolution. Likewise, the printed object does not look right.

But Prof. Moser said that with their new research, which they released recently, they showed a technique allowing them to use opaque resins. They used a video camera behind the resin, which enabled them to calculate the light’s path through the resin. Then, through detailed analysis, they developed a distortion correction algorithm, which they used to program the new 3D printer as it runs. The algorithm automatically corrects the light rays the printer delivers to every spot.

Even with opaque resin, their new process was still swift. For example, they printed a small Yoda character in only 20 seconds, achieving almost the same resolution as using transparent resin.

While their new 3D printer already works, the team will continue to work on the project, aiming to increase the resolution to ensure precision up to a micrometer level.

The EPFL scientists and engineers hope to produce various biological materials, including artificial arteries and other body parts. They also want to adjust their method so the printer can create several materials at once.