Supremely Tough New Glass Produced by German Researchers

Traditionally, glass is strong but brittle. Some materials can scratch its surface, and the glass can break when dropped or come in contact with another hard material.

Technology and new processes have made glass tougher; some resist breakage and high temperatures. Research and technological innovations continue to produce stronger glass, especially with the advent of mobile phones and electronic gadgets with glass displays. Thus, most mobile phones use tough cover glass, but can still break or shatter if dropped at a certain angle.

New tougher glass

But as the demand for tougher glass continues to rise, scientists do not stop their search for tougher glass. A few days ago, researchers at Germany’s University of Bayreuth and their partners in the U.S., China, and German Electron Synchrotron (DESY) announced that they have produced a tougher oxide glass. Using high temperatures and pressures, the researchers were successful in paracrystallizing aluminosilicate glass.

With their innovative process, the researchers created crystal-like structures that made the glass resist very high stresses, which it retained in ambient conditions. It proved that paracrystallization is a promising process for creating glasses that are extremely break-resistant.

Glass is suitable for modern technologies, but it has pros and cons. For example, glass is brittle, so it is prone to fractures and cracks, which hinders its application potential. Several studies to increase the material’s toughness while retaining its favorable properties have failed to achieve the expected results.

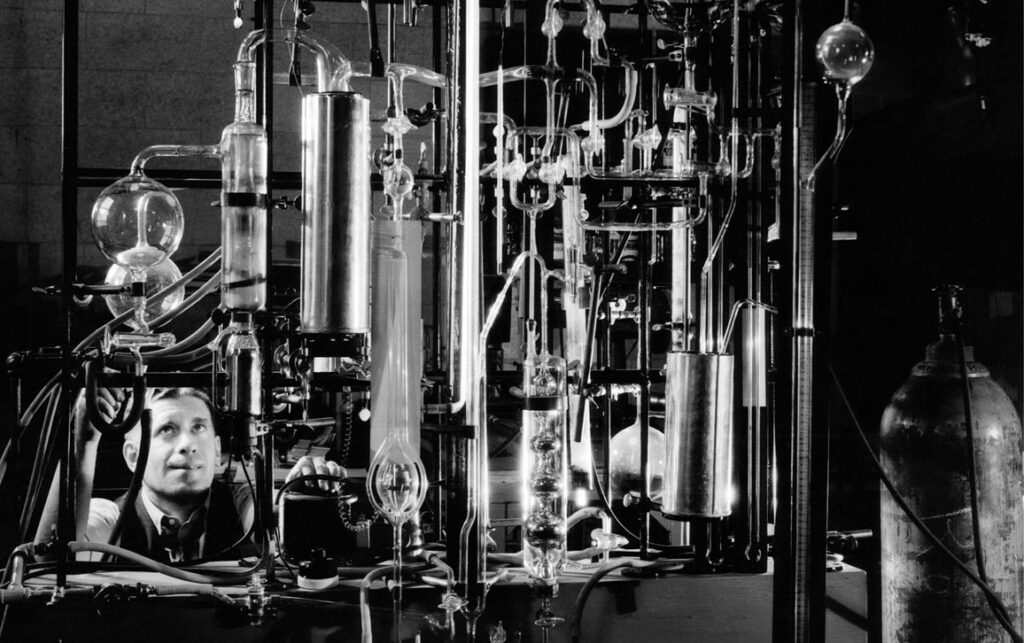

The researchers revised their approach by using oxide glasses with disordered internal structures. They utilized glass materials that are widely available commercially. With the use of aluminosilicate, which includes oxygen, boron, aluminum, and silicon, the research collaborators succeeded in giving structure to the material. They then applied high-temperature and high-pressure technologies at the University of Bayreuth’s Bavarian Research Institute of Experimental Geochemistry and Geophysics.

Their observations

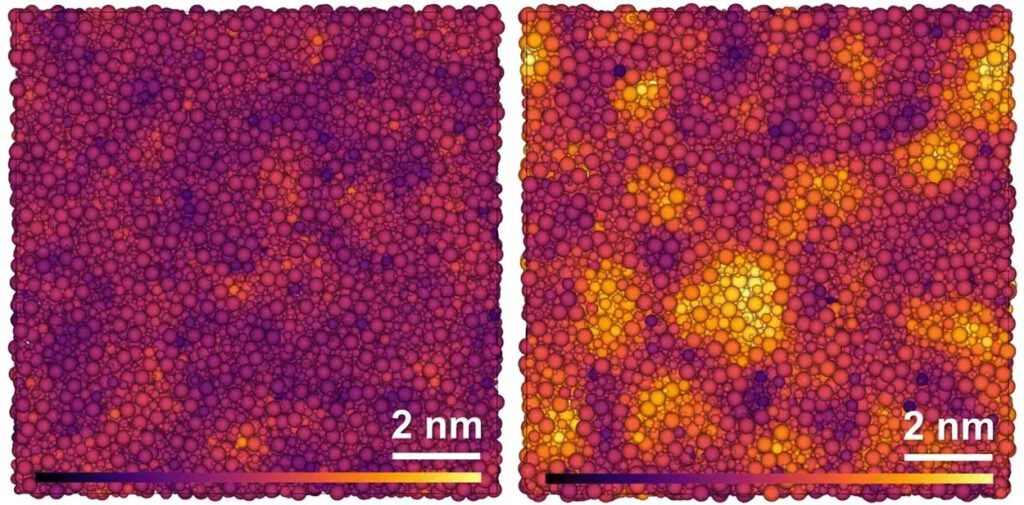

The researchers found that at a temperature of about 1,000 degrees Celsius and pressures between 10 and 15 gigapascals, the oxygen, boron, aluminum, and silicon atoms form structures similar to crystals. They have marked differences from completely irregular crystal structures but do not reach the clear and regular structure of crystals; thus, they are called paracrystalline. Another significant thing about aluminosilicate glass was the constancy in the paracrystalline structures even if the temperature and pressure drop to normal ambient conditions.

The new glass now reaches a value of up to 1,99 ± 0,06 MPa (m)¹/², the first time oxide glass with a toughness of such magnitude was measured. Moreover, the paracrystalline structures did not affect the glass’ transparency. They performed high-energy X-ray diffraction measurements at DESY’s PETRA III beamline P02.1 in Germany.

Extraordinary strength

According to the team, the force is mainly directed at the paracrystalline structures instead of the outside forces acting on the glass, causing cracks or breakage. The force can dissolve areas of the structures and turn back into their random, amorphous state. This process furthers the glass’s internal plasticity so it does not crack or break when exposed to external forces.

The new study’s first author, Dr. Hu Tang, said their discovery illustrates an effective strategy for developing a stronger, damage-tolerant glass. They plan to focus on this as they continue their research.