New Waste-Derived Polymer Coating Could Protect Industrial Pipes

Many industries need industrial piping. But exposure to the environment and various liquids can damage its exterior and interior surface. As a result, industrial piping needs a new coating for its protection.

Flinders University research

A research team at Flinders University in Adelaide, South Australia, developed a smart polymer coating. The research paper was included in the Polymer Chemistry Journal. Research associate Max Mann of Flinders University leads the project in cooperation with Dr. Bowen Zhang, co-author of the projects. Dr. Zhang is a researcher at the University of Liverpool in England.

Development stage

The new polymer coating is still in the development stage at Flinders but is already showing great promise. They produced the coating from an inexpensive blend of dicyclopentadiene, a waxy chemical compound that is a by-product of the petroleum refining process, and elemental sulfur.

They can manufacture the coating at a low temperature of 284 ºF (140 ºC). The lower temperature minimizes the occurrence of runaway reactions that are difficult to control.

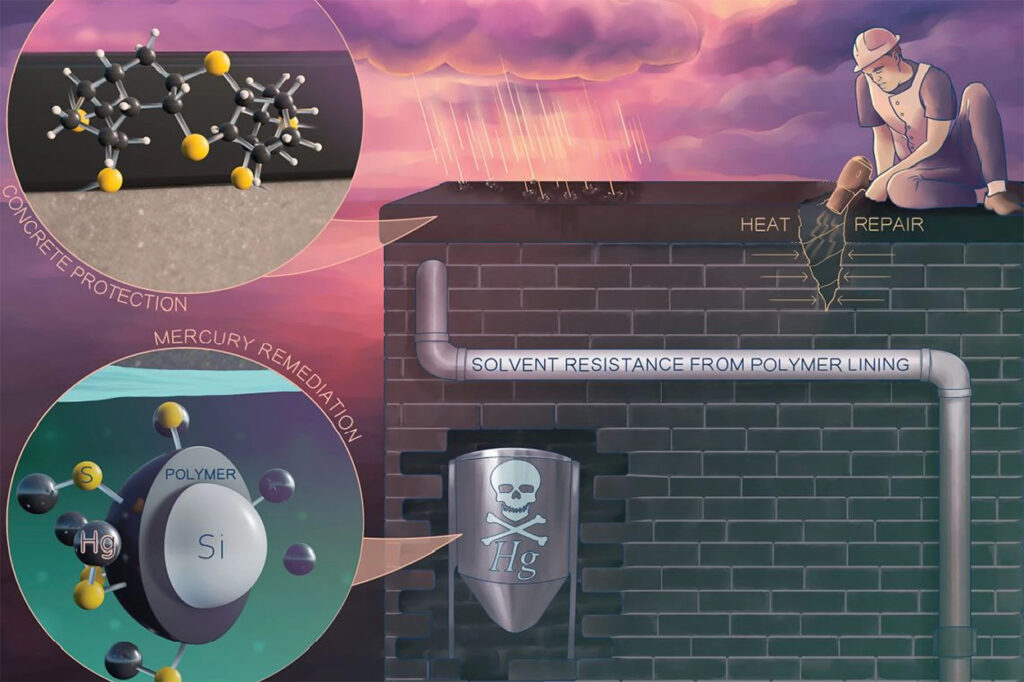

When they applied the coating to the inside of PVC, concrete, or metal pipes, the researchers claimed that the polymer forms a protective barrier. The coating prevents corrosion. It can also prevent damage caused by other liquids, including water, acid, and solvent, on concrete surfaces.

The coating also absorbs toxic metals like mercury from the water that passes through the pipes. The researchers already see the new polymer coating’s application in the gas and petroleum industry. The remediation procedures of this particular industry require the removal of pollutants from water and oil mixtures.

Another advantage of the new coating is that it is easy to repair. When scratched or gouged, you can repair the coating using heat. The sulfur-sulfur bonds within the coating break under the application of localized high-heat. But when the material eventually cools, the bonds reform uniformly.

Other researchers and scientists have good things to say about the new coating the Flinders University researchers are developing. They see it as a significant step in the development of coatings for multi-functional applications. They also envision the material’s sustainability and use of other inexpensive materials to better yet cheaper products.

Polymers

Polymer products are all around us. The material is included in synthetic fibers used for clothing. Many industries and businesses use fiberglass, plastic bags, epoxy glue, polyethylene cups, nylon bearings, polyurethane foam cushions, polymer-based paints, and even silicone heart valves.

Natural and synthetic polymers are used in various forms: organic and inorganic polymers, adhesives, plastics, caulks, ceramics, fibers, elastomers, and coatings.

Other research developments at Flinders

Aside from developing the new polymer coating, Flinders University has several more ongoing research works. They are also testing a marine coating that can take up copper from seawater. The coating releases the substance using electrical pulses, preventing the growth of unwanted organisms on the hulls of ships. They already started several sea trials of the new marine coating.

Many marine coatings typically use fungicide paints that release copper into the water. However, the effective killer of organic growth like barnacles and algae cause environmental concerns about the global increase of copper in the water.

Silicon-based coatings are effective antifouling agents when marine vehicles reach a certain speed. However, this type of coating is expensive and ineffective in build-up prevention when the marine vehicles are docked in port.