Popcorn, the New Sustainable and Environmentally Friendly Insulation

Insulation in buildings is a primary concern since it helps in several aspects. Primarily, insulation is used for thermal purposes, but it is also used for impact, fire, and acoustic concerns. For energy efficiency and comfort, insulation comes after proper air sealing as the most vital feature in commercial and residential buildings. Insulation minimizes the investment in cooling and heating equipment that consumes oil, gas, or electricity. Insulating a building or home reduces heating costs, resulting in lower carbon dioxide emissions.

Among the materials used for insulation, the most common are soil, cement, animal fiber, plant straw, plant fiber, wood fiber, perlite, vermiculite, urethane foam, polystyrene, rock wool, glass wool, and cellulose. Most of these use mineral fibers, animal fibers, or plastics.

New and sustainable insulation material

Recently, a University of Göttingen (Georg August University of Göttingen) research group announced their development of a new and sustainable insulating material that is more efficient, using something that is a favorite by many people worldwide—popcorn. The German research team developed the process to make insulation boards from granulated popcorn. Their research created material with excellent thermal insulation properties and repels water. In addition, popcorn foam is also a good fire protection material.

Since the material is plant-based, it is environmentally friendly and a sustainable replacement to the petroleum-based insulation products that are currently available.

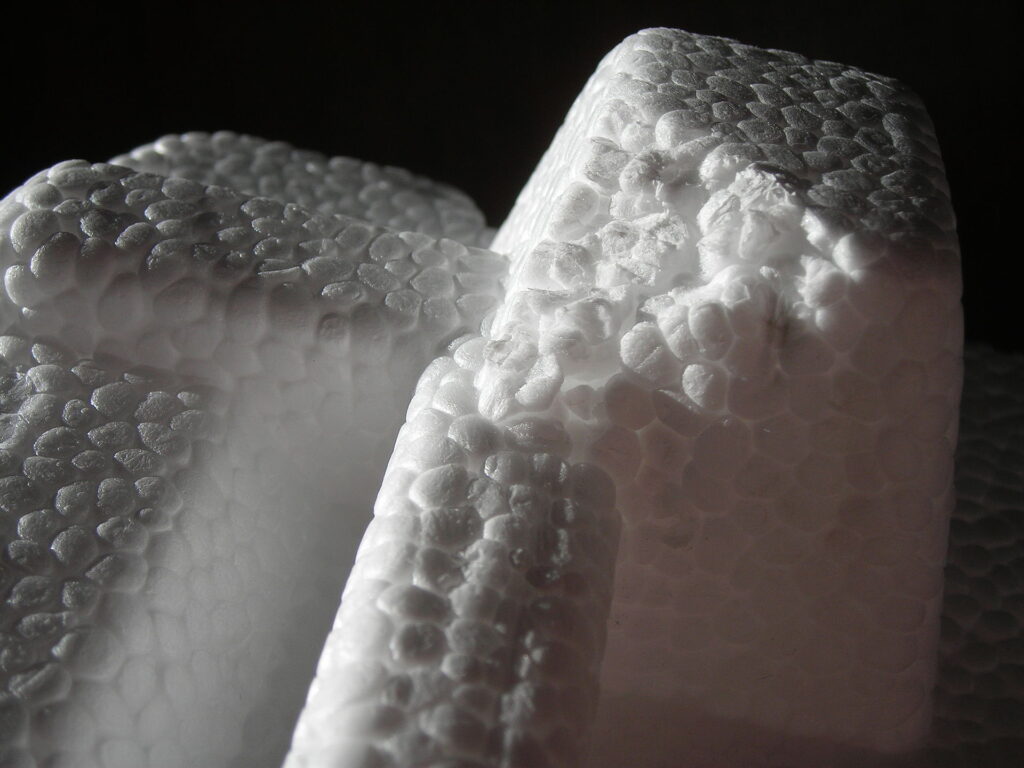

According to the research team, popcorn is sustainable as it comes from a renewable resource. The product is sturdy and recyclable. This means that you can use it for other applications. It can replace expanded polystyrene (EPS) foam used in shipping materials, disposable food containers, and insulation. Plastic pollution is a worldwide concern. Tons of these materials end up in landfills and bodies of water annually. While polystyrene is lightweight and cheap, it is not biodegradable and challenging to recycle.

The researchers say that the new popcorn foam absorbs heat better than expanded polystyrene foam and is less flammable. Once the popcorn foam is discarded, it can be used for biogas production or used as animal feed. Professor Alireza Kharazipour, head of the research group, added that their new process, based on what is used in the plastics industry, is more cost-effective in producing insulation boards. In addition, their process ensures that natural insulation materials will have widespread use.

The new popcorn insulation material is water-repellent, which will extend the life of the insulation and give the product more chances for practical applications.

Development of the popcorn foam

Professor Kharazipour said that the idea for a popcorn foam came to him ten years ago. Since then, the professor and his team began working on the process to develop an insulation foam that could be an alternative to EPD, biodegradable, renewable, and cheap.

The research team started shredding the maize grains into small granules to make their new product. They then used pressurized steam to ”pop” or expand the granules. The team next added a plant-protein-derived agent as a binder for the granules. The final step is to press the popcorn foam mixture into a mold. As soon as the agent is cured, the popcorn foam will retain its molded shape and is ready to use.

Popcorn foam will soon be available. The technology for the new process has been approved. The Bachl Group of Germany has the license to use the process commercially and produce the insulating product.