New Breath-Regulating Garments from Robotic OmniFibers

Athletes and performers learn breathing exercises to train and regulate their breathing to ensure they have the breath and energy to last until the end of their performance. The researchers at MIT and Sweden recently announced their development of a new kind of fiber that can be made into clothing.

The fiber is vastly different from the usual fibers woven into clothing. This one, which they call OmniFibers, are intelligent fibers that sense how much it is compressed or stretched and provide quick tactile feedback to the wearer through vibration, lateral stretch, or pressure.

The research team believes clothing made from this new fiber can help train athletes or singers to better control their breathing. They think it can likewise help patients recuperate from surgery or disease recover from breathing changes after surgery.

Fiber composition

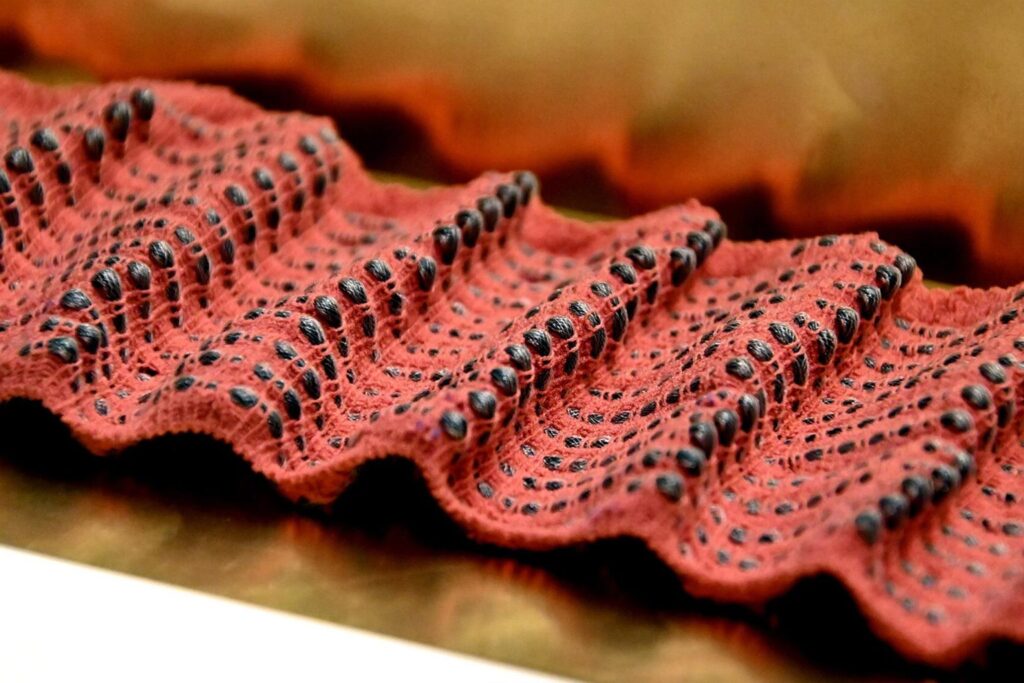

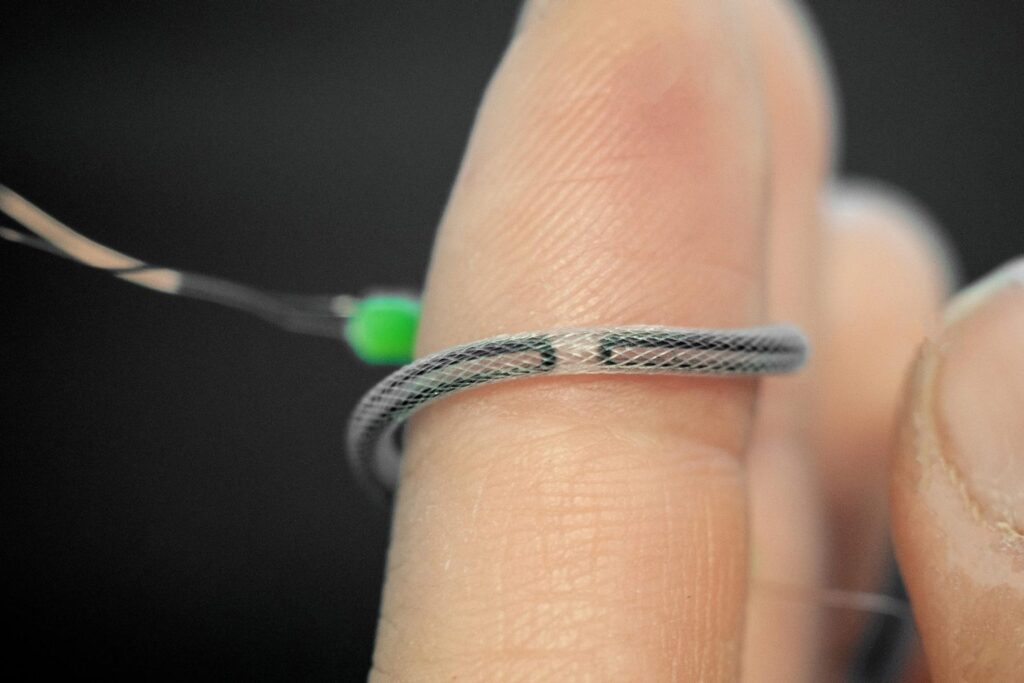

At the center of the multilayered fibers is a fluid channel. A fluidic system activates it and controls the geometry of the fibers by pressurizing and releasing a liquid medium. For example, water or compressed air could pass into the channel, which lets the fiber act like an artificial muscle. On the other hand, the fibers’ stretchable sensors detect and measure the degree of fiber stretching. Despite the fibers’ unique contents, the composite is thin and flexible, so it can be knitted, woven, or sewn using commercial machines.

The fiber has five layers. The innermost layer has a fluid channel contained in a silicone-based elastomeric tube. Next, a soft stretchable sensor detects the strain when there is a change in electrical resistance. The fourth layer is a stretchable braided polymer mesh to control the outer dimensions of the fiber. Finally, there is a non-stretchy filament providing the mechanical constraint on the overall extensibility of the thread.

Key features

The architecture of OmniFibers has several features:

- The fiber uses inexpensive materials.

- The yarn is exceedingly narrow, making it easy to produce the fibers into various fabric forms.

- The more important feature is its compatibility with human skin, as the outer layer of the thread is made of material that resembles regular polyester fibers.

OmniFibers has a fast response time. In addition, the variety and strength of the forces the fibers can transmit gives a quick feedback system for remote communications or training using the sense of touch (haptics).

According to the research team, most of the existing artificial muscle fibers have shortcomings because they have low-power efficiency, strenuous training processes, or are thermally activated, leading to overheating when the fabric contacts human skin. These deficiencies slow the response and recovery times, limiting their usability in applications that need immediate feedback.

Initial test

The researchers had an initial test application of their robotic OmniFibers by creating an undergarment that singers can wear, working closely with Kelsey Cotton, a classically trained opera singer. They want to monitor and playback the respiratory muscles’ movement through the material to gain kinesthetic feedback. In addition, the garment can provide the researchers with the information to help encourage optimal breathing and posture for an excellent vocal performance.

Their initial test was successful as the researchers gathered data of the movement from the strain sensors that are woven into the clothing. After translating the data, they learned that they were able to get the modes of actuation and the sensing that they wanted from the fabric, which could record and replay the complex movements from the physiology of the trained singer. The researchers were then able to transpose the knowledge to the body of a novice learner.

From the initial test, the researchers believe the same approach can help athletes control their breathing better in a given situation. They can monitor accomplished athletes performing various activities and stimulating the muscle groups while they are in action. Ultimately, they want to use garments made from OmniFibers to help patients regain their healthy breathing patterns as they recover from respiratory disease, including Covid-19 or significant surgery. It could also be used as an alternative sleep apnea treatment.

According to Ozgun Kilic Afsar, a visiting doctoral student and research affiliate at MIT, the physiology of breathing is very complex. There is little knowledge of which muscles people use for breathing and the composition of the physiology of breathing. The fabric they designed has separate modules to monitor people’s different muscle groups as they breathe in and out. They can replay the individual motions they gathered to stimulate each muscle group’s activation.

Hiroshi Iishi, a research team member, sees many other applications of the fibers to study various activities aside from breathing. He believes the fabrics created from OmniFibers can be used to develop gloves and sleeves to learn the dynamic movements of calligraphers, for example, or to capture the movements of Olympic athletes to improve their skills.

Ms. Afsar plans to continue their work to develop an entirely new system for OmniFibers, including miniaturizing compressed air supply and control electronics. The team also plans to expand the manufacturing system so they can create longer filaments. In the ensuing months, they will be experimenting on using the system to transfer the skills of an expert singer to a novice and later move on to experiments involving movement practices of dancers and choreographers.