CSU Scientists Develop a Fully Recyclable and Biodegradable Polymer

Polymers are substances that consist largely or entirely of similar units bonded together. They can be natural like shellac and amber or synthetic like plastic and resin. They are highly useful substances or materials used for various purposes. However, they also contribute significantly to the problem of solid waste in different parts of the world. Plastics used in packaging, in particular, are a big part of the garbage collected from homes and businesses; and almost every government worldwide finds it very challenging to properly get rid of them. A massive amount of them are already polluting the oceans.

The good news is that a team of scientists from Colorado state University (CSU) have finally developed a polymer that is 100% biodegradable and recyclable. Chemists from CSU successfully produced a material that can be fully recycled and does not pose a major threat to the environment. Their research has been published in the journal Nature Chemistry.

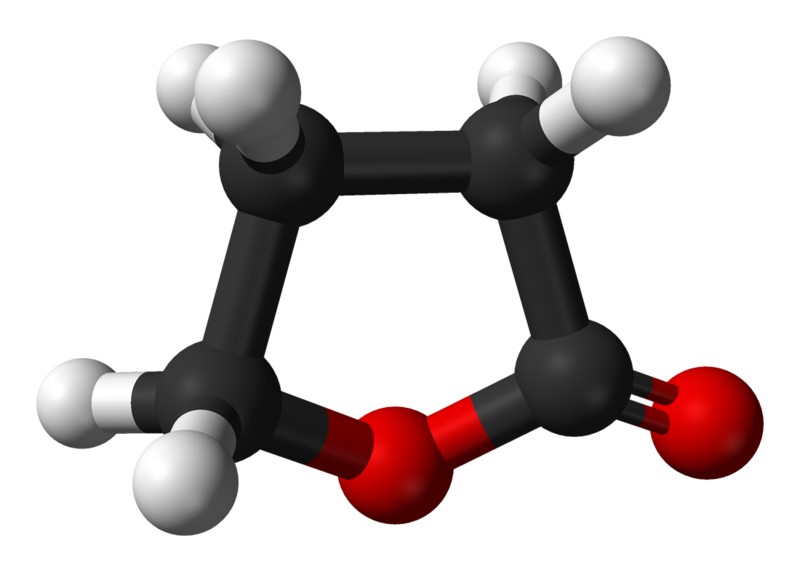

Poly(GBL)

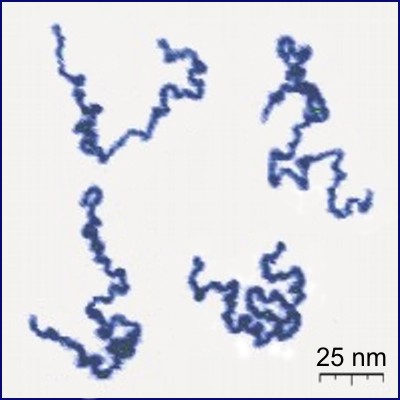

Referred to as poly(GBL) or a polymerized gamma-butyrolactone, this new material can be considered as the basis of petroleum-free plastic products. It is notable for being entirely biodegradable and completely recyclable. It can usher in the era of pollution-free plastics. This polymer can be created into various useful things and can be easily broken or molten down to its original building blocks to be created into new objects again.

To create it, the scientists chose a biomass compound which is being regarded by the US Department of Energy as one of the 12 most suited compounds/substances to replace petrochemicals. This compound is gamma-butyrolactone (GBL), a colorless water-soluble liquid commonly used as a reagent, cleaning solvent, and superglue remover. The scientists made use of metal-free and metal-based catalysts and employed a process that calls for specifically designed reaction conditions.

Defying Earlier Beliefs

Interestingly, GBL has long been believed to be impossible to polymerize. Scientists thought that overcoming the thermodynamics restraints surrounding GBL is already out of the question. Attempts were already made several years ago but scientists couldn’t turn GBL into a polymer at anything outside insanely high levels of pressure. Thankfully, the CSU scientists suspected that the earlier conclusions were flawed so they decided to find a way to build a polymer with GBL and got the results they hoped to achieve. It’s an added bonus that they found the way to do not just create a linear polymer with GBL but also cyclic ones.

Aren’t Plastics Already Recyclable?

Indeed, plastics can be recycled. Durable plastic bottles or containers can be repurposed or be made as components for the creation of new useful objects. They can also be molten or processed to be made as materials for the production of new things. However, the process yields unwanted byproducts. Even the biodegradable plastics being used at present are not necessarily recyclable in terms of “feedstock recycling.” Plastic breakdown produces substances that can become organic pollutants. The poly(GBL) produced by CSU scientists is 100% biodegradable and recyclable. What sets it apart from other polymers is that it can “reset” to its monomer components after getting heated for an hour at 220°C (for linear polymers) and 300°C (for cyclic polymers).

Invention or Discovery?

If you have read about this news on other sites, you may have been confused by how it is being referred to as a “discovery” by some and as an “invention” by others. Basically, what happened with the development of this fully recyclable polymer is that scientists simply discovered that the long-held belief that GBL is inherently un-polymerizable is incorrect. They proceeded to finding out the right conditions and methods to enable polymerization so it can also be said that they also invented it or at least invented the process that now allows the material to exist.

Advantages and Applications

Aside from the advantages already mentioned earlier, it’s worth noting that poly(GBL) can be compared to P4HB, a commercially used bioplastic (biodegradable plastic) derived from bacteria. Poly(GBL) is an environmentally-friendly plastic that is not as expensive to produce as the P4HB. It can be used for a wide array of applications especially in the food industry, except perhaps in the manufacture of microwaveable containers. More tests still need to be done to determine the suitability of poly(GBL) but it can be safely assumed that this new polymer is one of the notable developments in materials science in recent years. A provisional patent has already been filed for this new polymer with the assistance of CSU Ventures.