The Future of Material Science: Autonomous Robots and AI Enhance Energy Efficiency

The Dawn of Autonomous Material Research

In the evolving field of material science, the integration of autonomous robots and artificial intelligence (AI) is setting a new benchmark in research and development. At Boston University’s College of Engineering, a groundbreaking project showcases this integration’s potential. A robot, known affectionately as MAMA BEAR—Mechanics of Additively Manufactured Architectures Bayesian Experimental Autonomous Researcher—has been pioneering the development of shapes with unprecedented energy absorption capabilities. This article explores how AI-driven autonomous systems are revolutionizing material science, pushing the boundaries of what’s possible in energy efficiency and safety applications.

Innovations in Energy Absorption

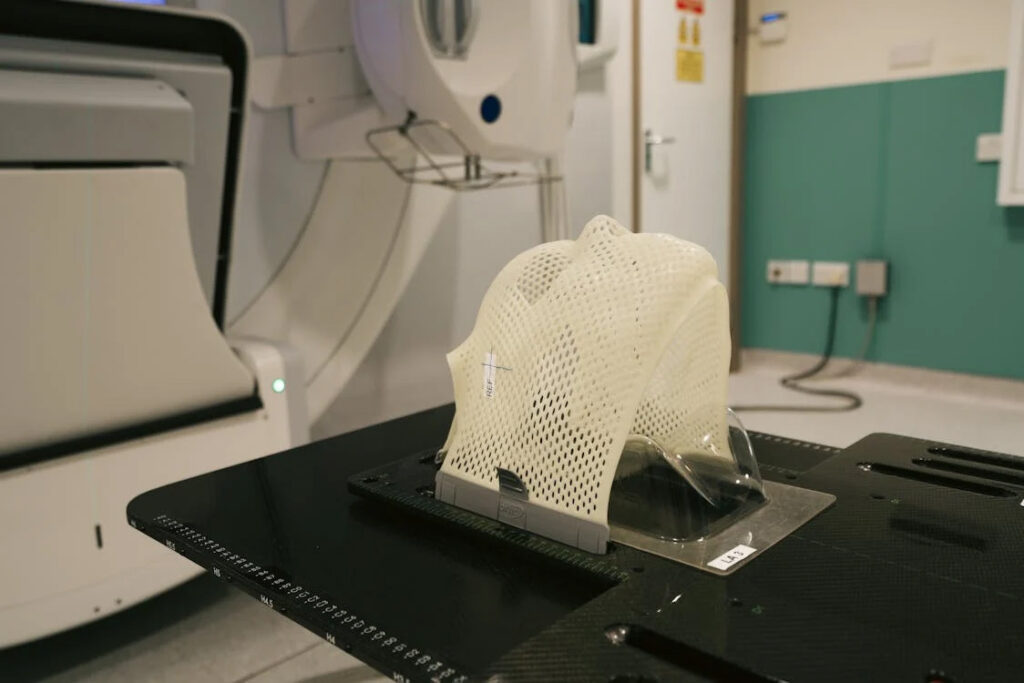

MAMA BEAR’s quest began in 2018, driven by the vision of Keith Brown, an associate professor of mechanical engineering, and his dedicated team. The robot autonomously designs and tests small, 3D-printed structures, assessing their ability to absorb mechanical energy—a critical property for applications ranging from vehicle bumpers to protective gear. Using a 3D printer, the robot creates various shapes, which it then crushes under a pressure equivalent to an adult Arabian horse standing on a quarter. By recording the energy absorbed and the deformation endured by each shape, MAMA BEAR can adjust future designs, optimizing them for better performance based on a method known as Bayesian optimization.

Practical Applications and Real-World Impact

The implications of this research extend far beyond the laboratory. The data and insights gained from the thousands of experiments have already begun to influence real-world applications. One notable application is in the design of new helmet padding for U.S. Army soldiers, aiming to provide better protection while maintaining comfort. The innovative designs derived from MAMA BEAR’s research offer a balance between strength and impact absorption, ensuring that the materials are not too harsh on the user while still providing substantial protection. This technology promises not only enhanced safety but also increased efficiency in producing and testing new material forms.

Expanding Horizons: Beyond Single Applications

The success of MAMA BEAR extends beyond specific products like helmet padding. The technology’s potential is being tapped into various fields requiring high-performance, energy-absorbing materials. For instance, the automotive industry can use these insights to develop more effective car bumpers that better protect passengers during collisions. Similarly, the shipping industry might utilize these advanced materials for packaging solutions that safeguard delicate electronics during transport. This broad applicability underscores the versatility of autonomous robots in material science, highlighting their capability to adapt and innovate across multiple domains, thus setting the stage for widespread industrial transformation.

Shaping the Future of Materials

As we continue to explore the capabilities of autonomous robots and AI in material science, the potential for innovation appears limitless. The work of MAMA BEAR and Boston University’s KABlab is just the beginning. These rapid technologies, advancements that are going to be significantly big, can bring up safe and energy-efficient materials in absorbing energy, which could revolutionize industries from automotives to sports equipment. Combining machine learning with automation and imaginative scientific curiosity will open avenues to much smarter, faster, and effective general scientific research. It is a very bright example that the future of materials will not only be in what but in how to create them at the same time. That is how, in the following explanation, technology and science together push the frontiers of knowledge and application, promising a world that is safer and more efficient.