The Future is Here: Tiny Chip Transforms 3D Printing with Light Steering Technology

A coin-sized photonic device using light guiding technology to change the production of items is changing 3D printing. Developed in partnership by scientists from the University of Texas at Austin and the Massachusetts Institute of Technology (MIT), this ground-breaking technology is a major breakthrough that shrinks 3D printers to the size of a palm and increases their efficiency and adaptability. In this paper, the design, functioning, possible applications, and collaboration that made this technology possible are reviewed.

Innovative Design of the Chip-Based 3D Printer

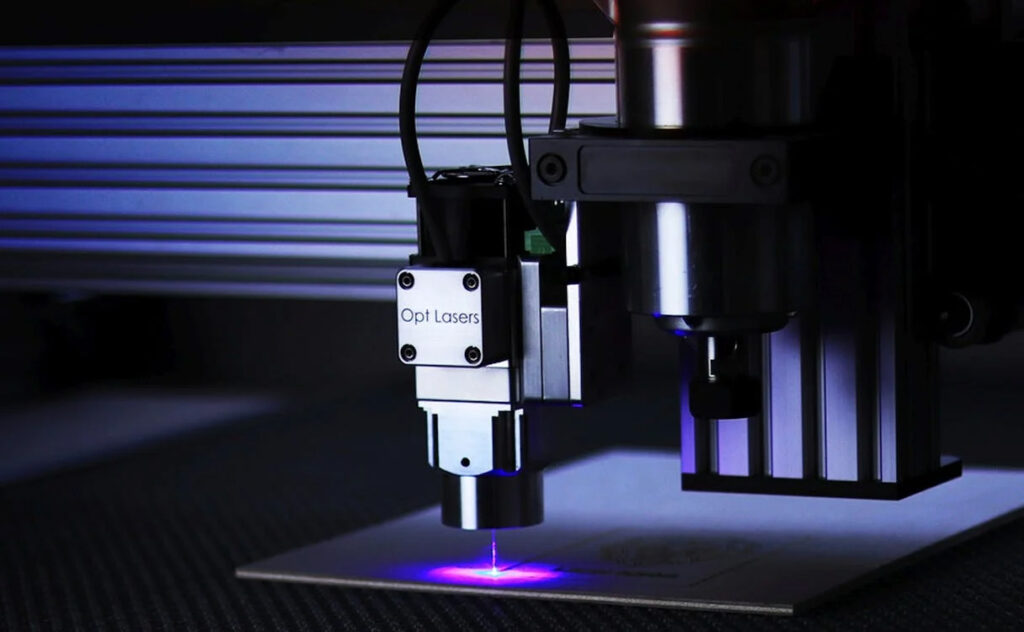

A millimeter-scale photonic chip, which radically changes the conventional 3D printing process, is the mainstay of this technical innovation. An array of microscale optical antennas on this device electronically controls light beams, unlike traditional 3D printers that use mechanical components to position and concentrate light. Reconfigurable visible light beams produced by the chip accurately cure a specifically designed resin into solid objects by combining silicon photonics with sophisticated photochemistry. This integration not only makes the printer smaller physically but also drastically lowers the amount of moving components, which improves dependability and robustness.

Operational Mechanism and Printing Process

The operational excellence of the chip-based 3D printer lies in its ability to direct light precisely where it is needed without mechanical intervention. When powered by an external laser, the optical antennas within the chip emit a steerable beam of light, which is then focused onto a layer of photocurable resin. Electrical signals control the beam’s direction, allowing for the rapid solidification of the resin in intricate patterns. The resulting process is not only faster but also allows for greater control over the shape of the printed objects, opening up possibilities for more complex and detailed designs than ever before.

Broad Spectrum of Applications

This chip-based 3D printer has a plethora of different and broad possible uses. Customized prostheses and surgical instruments catered to the demands of each patient can be manufactured in the medical sector right at the point of care. Professionals in engineering and construction may bring these printers to project sites to make components on demand, cutting down on lead times and storage and transit expenses. Moreover, because of its mobility, the printer may be used in isolated or underdeveloped places, giving users instant access to materials and tools that would not be available otherwise.

Collaborative Development and Technological Synergy

This chip-based 3R printer was developed through a fruitful partnership between the Page Group at UT Austin and the Notaros Group at MIT. Together, photochemistry and silicon photonics knowledge allowed for the development of a device that combines the two fields. Working together, the researchers optimized the photocurable resin’s and the photonic chip’s architecture to guarantee that the finished product could function well in a variety of environments. This cooperation project sets a benchmark for the next technical advancements in 3D printing and other domains and also illustrates the interdisciplinary nature of modern scientific research.

The advent of the chip-based 3D printer, which packs the features of conventional, large 3D printers into a palm-sized device, has finally heralded a new era in additive manufacturing. This breakthrough raises the precision and speed of 3D printing and expands its uses in a number of industries, including remote construction and healthcare. The ability of this technology to completely transform the way we think about, create, and use on-demand manufacturing and quick prototyping will make it an essential tool in the contemporary technological environment.