Can an Eye-Like Curved Camera Sensor Improve Camera Performance?

![By The Conmunity - Pop Culture Geek from Los Angeles, CA, USA (CES 2012 - Sony press event - cameras) [CC-BY-2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons](https://techtheday.com/wp-content/uploads/2014/06/Sony-cameras.jpg)

By The Conmunity – Pop Culture Geek from Los Angeles, CA, USA (CES 2012 – Sony press event – cameras) [CC-BY-2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons

Camera technology has greatly improved over the years. Before the end of Moore’s Law finally makes its prominent manifestation, improvements in computer and electronics hardware have greatly benefitted cameras. Cameras have become smaller without compromising quality. Sensors or camera modules in general have been made tinier to fit into slimmer bodies. This has even led to the virtual demise of point-and-shoot cameras as smaller but powerful camera modules can already be integrated with smartphones.

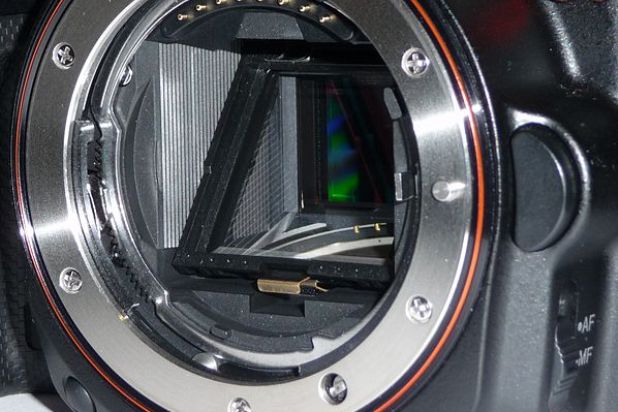

This year, Sony, one of the leading companies when it comes to camera technology, introduces another camera innovation: the curved camera sensor. The Japanese camera maker has developed a way to make their CMOS sensors more effective in gathering light by bending them, making the photon-receiving side concave.

Unlike the seemingly senseless use of curves by Samsung and LG with their Galaxy Round and LG Flex smartphone displays, Sony employs curvature to create real benefits. Sony announced this imaging tech innovation at the 2014 Symposia on VLSI Technology and Circuits in Honolulu, Hawaii. The following are the important details you would want to know about this new camera tech from Sony:

1. The curved sensor design mimics the curvature of the human eye.

Sony’s curved sensors have been intended to mimic the eye. It’s biomimicry or biomimetics of sorts, something that rarely leads to undesirable results. The eyes of living organisms, after all, are arguably the best models in coming up with ways to improve cameras and other technologies related to vision.

2. Sony uses a special “bending machine” for the process.

The company has not shared information about this special bending machine but Kazuichiro Itonaga, a device manager at Sony’s Research and Development facility in Atsugi-shi, has shared some interesting details regarding the sensor bending or curving process. In an interview with IEEE Spectrum, Itonaga implied that the CMOS sensors are first produced as final sensor products before they are subjected to the bending process. He added that ceramic was added after bending to stabilize the sensors’ form. Basically, it’s only the bending that is new in this new camera technology, but something this simple is expected to offer very palpable benefits.

3. The various benefits derived from this sensor curving are as follows:

- Better light sensitivity – According to Sony’s engineers, the curved camera sensor is estimated to be 1.4x more light sensitive at the center and around 2x more sensitive at the edges. This means better camera performance even in challenging lighting situations. If you are wondering why the center has the lower light sensitivity improvement, it is because the sensor is curved in a way that the concave side is the one facing the lens or light source. As such, the edges are the ones closer to the lens while the middlemost part is the farthest.

It is important to note, however, that the curving does not make the CMOS sensor more sensitive to light. Better light sensitivity here refers to the overall performance of the camera module, not to the light sensitivity of the CMOS sensor. What’s responsible for the enhanced sensitivity is the use of a brighter lenses (that the curved sensor enables) and the more efficient transmission of light into the sensor, as explained in the next benefit in this enumeration.

- Pairing with a flatter lens and larger aperture – Because of the curved CMOS sensor’s geometry, it can be paired with a flatter and brighter lens (larger aperture). These components let more light in. On the other hand, the curved camera sensor has its photodiodes consequently bent toward the center, allowing them to more directly receive the light that go through the lens. With a standard flat sensor, the light that passes through the lens hits the photodiodes obliquely.

- Lower dark current noise – The bending of the CMOS sensor causes the alteration of the band gap of the silicon devices in the sensor region. This creates the benefit of lower noise attributable to dark current or the current (that should not exist) that passes through a pixel even when there’s no external light that should be responsible for such current.

According to Itonaga, Sony already has two variants of these curved sensors. One is a full-size 43 mm chip intended for digital cameras. The other one is a smaller 11 mm model designed for mobile phones. Regarding the production schedule, Itonaga said that Sony has already made some 100 full-size sensors. There’s no specific date for mass production but he said “we are ready.”

The curved sensors from Sony are expected to bring improvements to photography, especially when it comes to low light shooting performance. This new sensor will be particularly useful for smartphones and other mobile devices since, until now, despite all the claims made by several companies, low light shooting with smartphones is still noticeably inferior compared to the performance of dedicated cameras.