Breaking Records with Counter-Intuitive Nanomaterial Expansion

Engineers at the University of Western Ontario have achieved a groundbreaking development in the realm of material science with the creation of a novel nanomaterial that defies conventional logic. By stretching tungsten semi-carbide nanosheets in one direction, they remarkably expand perpendicular to the applied force. This counter-intuitive behavior mirrors the opposite of what is typically observed in materials like rubber or balloons, which contract perpendicular to the direction of stretch. The discovery opens up new avenues in nanotechnology, highlighting the potential of two-dimensional materials to push the boundaries of what is physically and practically possible.

Material Design and Composition

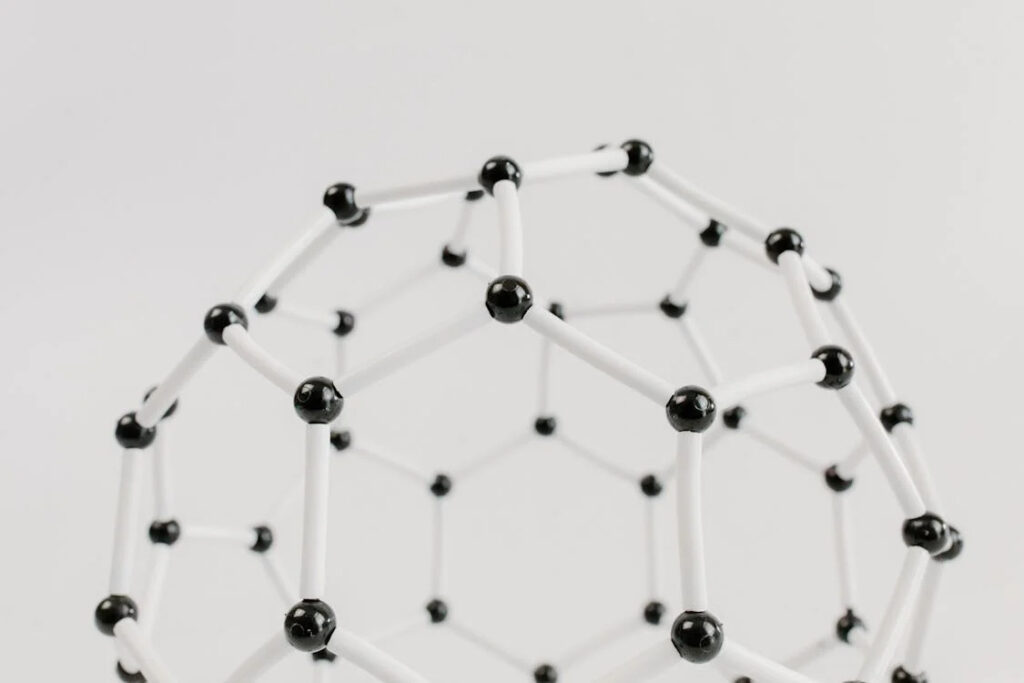

The unique structural design of the tungsten semi-carbide (W2C) nanosheets is central to their remarkable properties. Each sheet is composed of a repeating pattern of two tungsten atoms for every carbon atom, arranged to mimic a dimpled surface similar to an egg carton. This intricate atomic configuration is what enables the material to behave auxetically—expanding perpendicular to the direction of applied tension. The unconventional layout of atoms allows for flexibility and expansion, setting this material apart from traditional materials which typically contract perpendicularly when stretched.

Innovative Fabrication Techniques

Creating the W2C nanosheets required a departure from conventional chemical synthesis methods. The team led by Stocek and Fanchini employed plasma physics to overcome the limitations faced by previous researchers. They developed a novel instrument that generates a plasma, an ionized state of matter, rather than using traditional furnaces. This approach allowed for the precise manipulation of tungsten and carbon atoms to form the desired two-dimensional structure without the typical neutral particle by-products of high-temperature gas reactions. This breakthrough in fabrication techniques marks a significant advancement in the field of material science.

Performance and Capabilities

The performance of the tungsten semi-carbide nanosheets is characterized by their unprecedented ability to expand by up to 40 percent per unit length when stretched, a significant leap from the previously recorded 10 percent. This exceptional capacity for expansion does not merely translate to physical versatility; it also enhances the material’s electrical conductivity. When stretched, the nanosheets do not thin out and lose conductive properties but instead become more conductive, a trait that could revolutionize how materials behave under mechanical stress.

Applications and Practical Uses

The range of applications that may be developed from W2C nanosheets influences a broad area and it is very beneficial for many sectors. Thus, one immediate application of this could be the building of a new kind of strain gauge that would be used in monitoring when it is put under the functional loads of, say, aircraft wings or household plumbing systems. Furthermore, possessing high electrical conductivity and flexibility, they are the right kind of nanosheets to be a part of stretchable electronics and wearable technology. Their originality could find application in the development of more robust and efficient sensors and devices that would be capable of an environment change detecting response, the improvement of functionality and connected systems.

The development of such tungsten semi-carbide nanosheets now represents a significant stride forward in materials engineering, with the new benchmark capabilities this type of two-dimensional nanomaterial possesses. With outstanding swelling and improved electrical conductivity, these nanosheets make diverse fields of applications from industrial sensors to wearable technology poised for a makeover. This development dares our basic understanding of material property, not just the technology used to process materials but also highlights the possibilities of scientific exploration and advanced manufacturing techniques to make solutions that could change everyday technology.